-

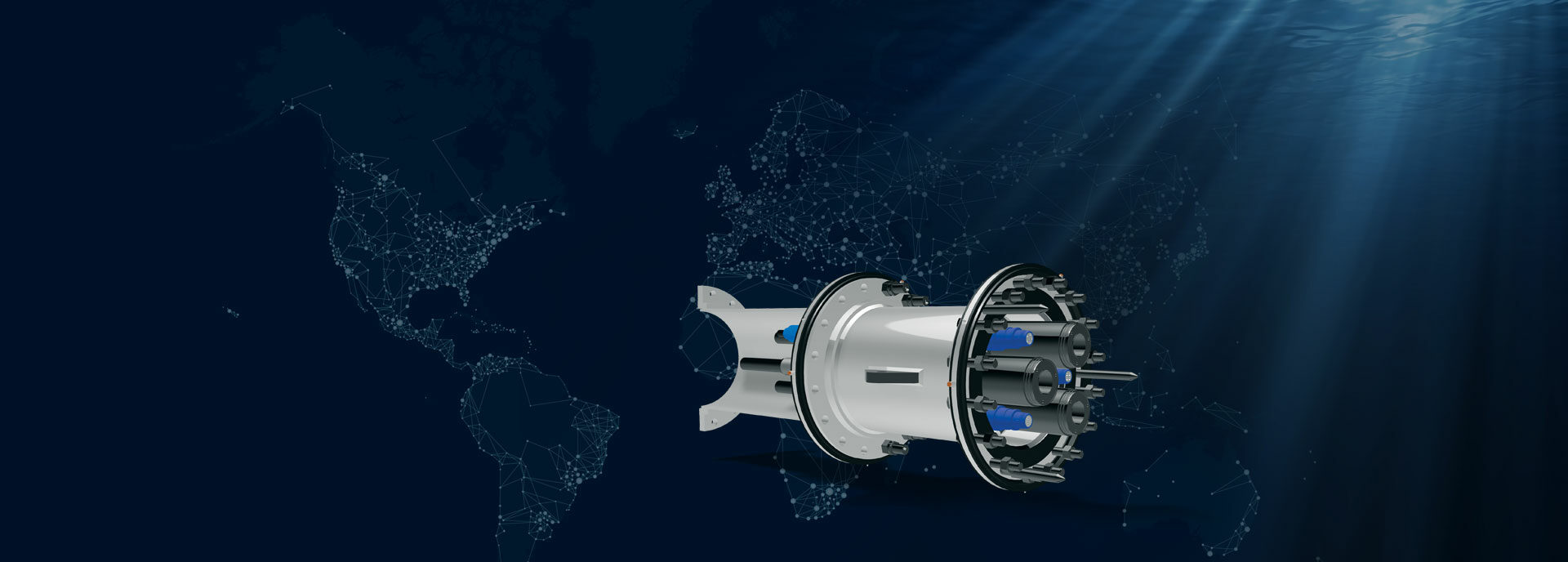

global leaders in bespoke subsea connectivity solutions

we design, engineer, manufacture, test and certify -

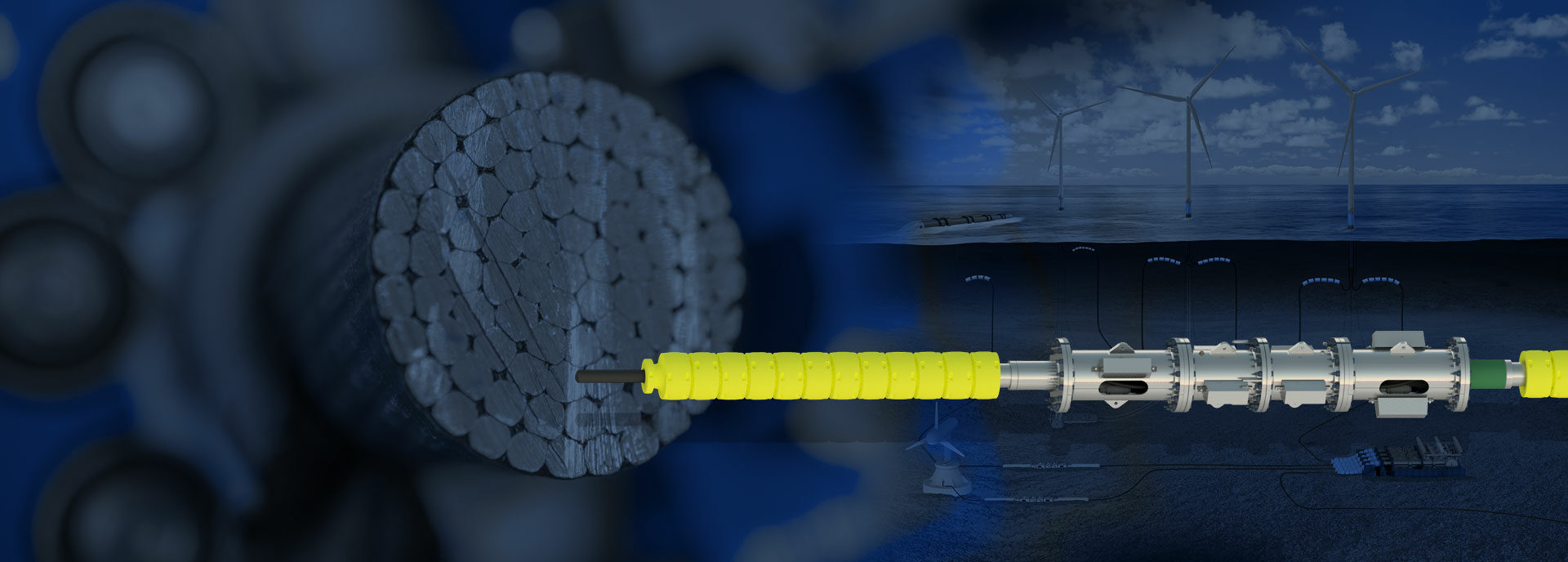

nearly 4 decades of knowledge and innovation

so where did it all begin?